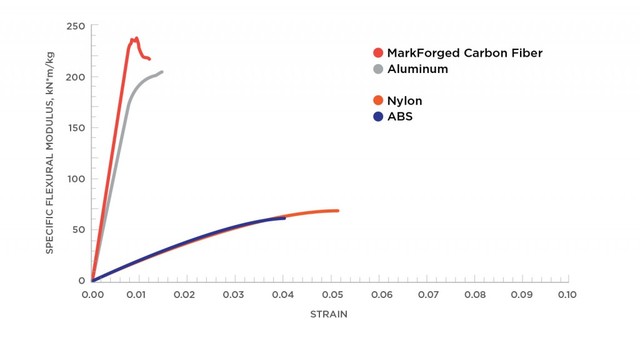

Designed to overcome the strength limitations of traditional 3D printed materials, the revolutionary Mark One 3D printer is the world’s first 3D printer designed to print continuous carbon fiber. Now you can print parts, tooling, and fixtures with a higher strength-to-weight ratio than 6061-T6 Aluminum.

MarkForged was founded by an aerospace engineer – the kind of person who loves pushing the envelope. After years of designing and manufacturing high-performance composite race car wings, Greg Mark realized that you could use 3D printing hardware to automate the composite layup process. Many print heads and patents later, the Mark One was born.

The magic is in the print head. The special blend of thermoplastics immediately hardens during printing. No nasty chemicals. No post curing. This is one 3D printer you’d be happy to sit next to.

The incredible strength of carbon fiber comes from the long, continuous strands that carry load down the entire part. This is why space shuttles, rockets, and Formula 1 cars are constructed from continuous strand carbon. And it’s how we print. Don’t settle for plastic with a dash of chopped carbon fill. Longer is stronger.

And when you don’t need the world’s strongest material, the Mark One 3D prints a range of other materials to help professionals design and iterate quickly. Make super tough parts with Nylon Filament. Or load tried and true, low-cost PLA filament for those quick form and fit prints. And if you need the best cost-to-strength solution, crank out a print using a Fiberglass Filament that uses the same patented Continuous Filament Fabrication.

Pre-order details are expected to be released shortly. Currently you can sign up to be notified when pre-orders begin.